Pipeline Geometry Inspection

Geometry Inspection (Electronic Geometry Inspection)

Athena is the leading provider of geometry inspection services for new construction pipelines and is the preferred service provider for pipeline operators such as GAIL, IOCL, BOCL, HPCL, GIGL, OPAL, and GSPL. We have inspected over 3000 kilometres of pipeline ranging in size from 4 inches to 36 inches. Our company has been involved in the inspection of major newly constructed pipelines for various operators. For example, we have inspected the Kandla-Gorakhpur Pipeline, which is the second longest LPG pipeline.

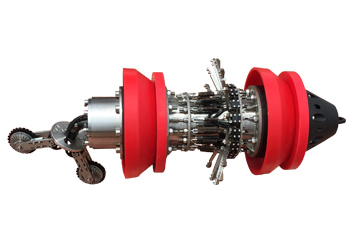

Our in-line inspection tool is designed to record geometric conditions of pipelines, such as dents, buckles, wrinkles, ovality, and occasionally indications of significant internal corrosion by sensing the shape of the internal surface of the pipe. Mechanical deformations can also cause the growth of corrosion, and corroded dents can pose a serious threat to pipeline integrity. Changes in the diameter or bore of the pipeline's circular shape can affect the flow of product and cause increased power consumption required for product transportation.

We offer advanced geometry inspection services to detect and accurately measure any changes in diameter in order to prevent serious threats to pipeline integrity. Caliper surveys for new construction pipelines are mandatory for establishing a baseline and confirming the existence of any defects prior to the commissioning of the pipelines.

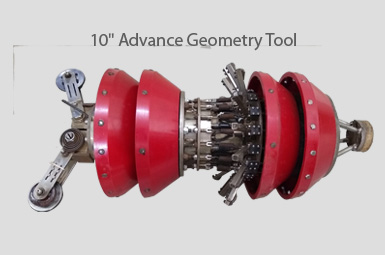

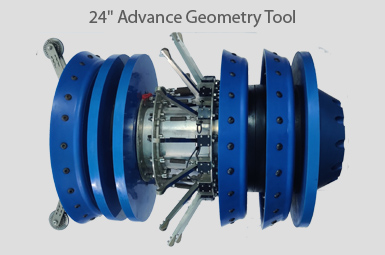

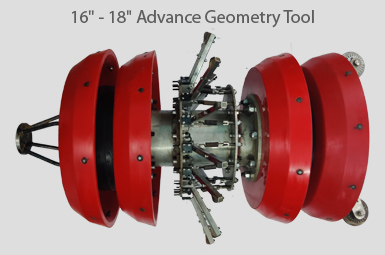

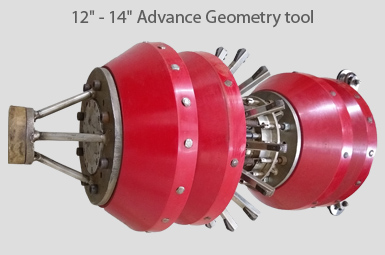

DATA ANALYSISOur advanced geometry tools, equipped with finger-mounted arms and advanced sensors, make direct contact with the pipe wall and cover the entire 360-degree circumference of the pipe. Any change in pipeline diameter can be detected by arm movement and recorded on the onboard electronic unit for further analysis. High-accuracy odometers are in place to record the axial distance of the pipeline, aiding in the identification of any defects along the pipeline axis.

Heading 3

Add text here.. Add text here.. Add text here.. Add text here.. Add text here.. Add text here..Heading 4

Add text here.. Add text here.. Add text here.. Add text here.. Add text here.. Add text here..Heading 2

Add text here.. Add text here.. Add text here.. Add text here.. Add text here.. Add text here..Heading 1

Add text here.. Add text here.. Add text here.. Add text here.. Add text here.. Add text here..Data downloaded from the tool after the tool run goes for further analysis and any anomalies that is above 5% is reported immediately and anomalies ranging from 2% to 5% are covered in final report submitted after complete data analysis.

Advance Geometry used for are designed and capable to meet minimum requirement as per Pipeline operator’s standards.